Safe Laser Welding In The Production Of Batteries

OphirBlog

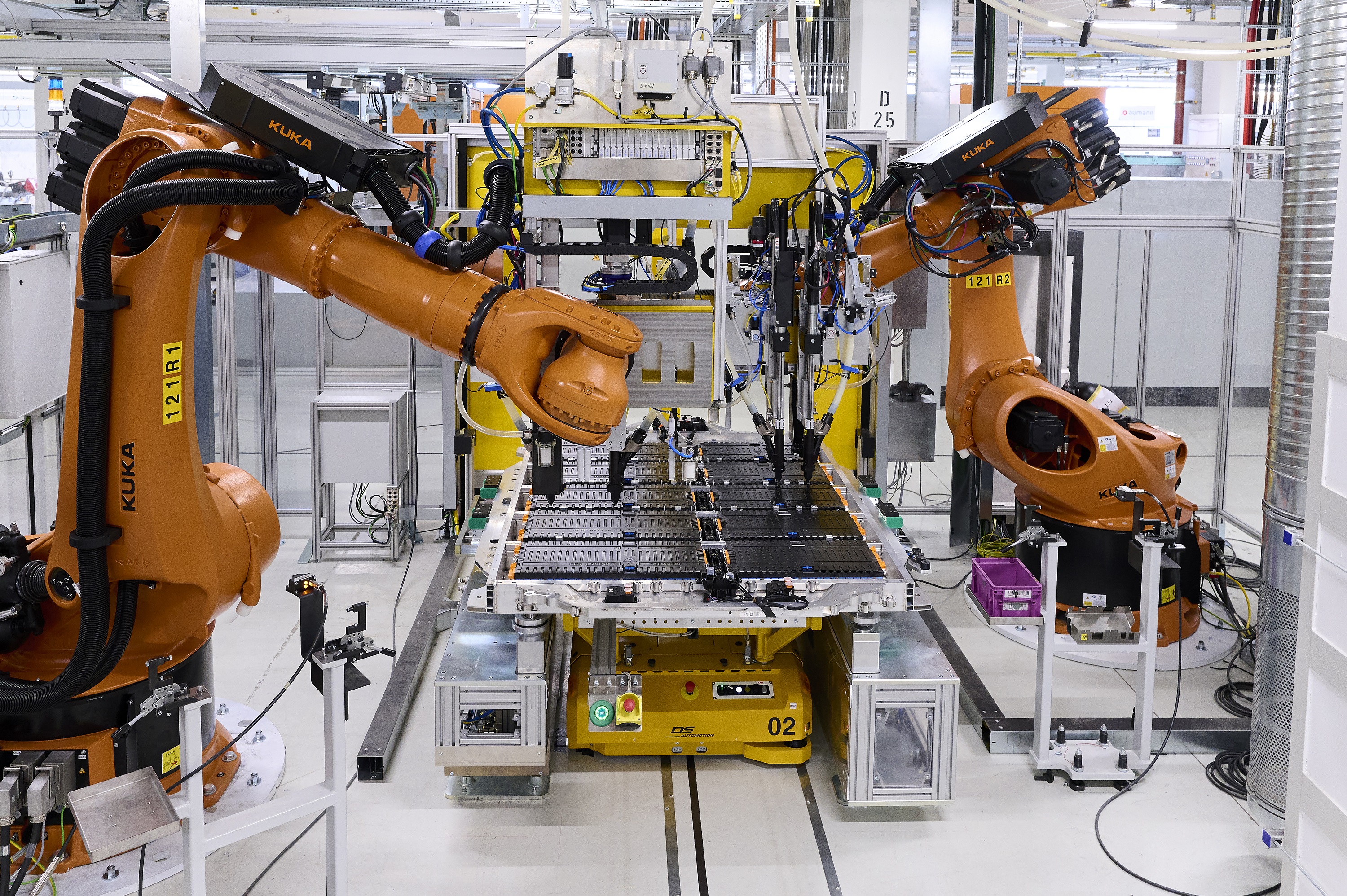

Battery modules are the beating heart of every electric car. They ensure mobility and security, and their reliability determines whether a vehicle is accepted or not.

The BMW Group launched the i3, the first fully electric production vehicle, back in 2013 – so the company is well aware of the pitfalls of battery production, which grow in complexity with every uptick in capacity.

Up to 144 laser welds are required for contacting a 5th-generation battery module.

Thanks to Ophir BeamWatch Integrated systems, the automaker can check the laser beam before manufacturing each new module, independent of cycle times and with success. Before, in order to confirm ideal weld-in depths, spot checks by means of micrographs were carried out on a weekly basis.

Read full case study here

Subscribe to receive laser news beamed to your inbox

Pick the subjects that are most relevant

- Industry news

- Power & Energy Meters

- Laser Beam Profilers

- LED Measurements