Sustainability in 3D Metal Printing

OphirBlog

Raw materials and energy are precious, and the agreed-upon climate targets are ambitious. To achieve greater sustainability, manufacturing processes must be redesigned to conserve resources. Companies have long recognized the opportunities that additive manufacturing offers in this context. A case in point is the rapidly growing field of 3D metal printing – and it is precisely here that, in the interests of sustainability, energy and material consumption must be optimized. Key to this is continuous testing of process parameters.

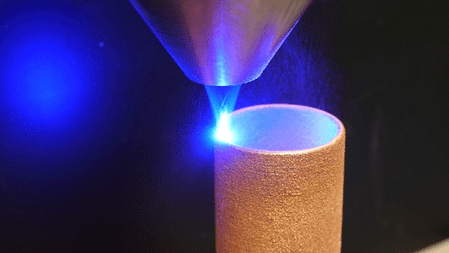

In laser powder bed fusion (LPBF), a focused laser beam is used to melt powdered metal, layer by layer. This technology has opened up new possibilities for a wide variety of applications. In designing components for diverse applications ranging from industrial to medical to decorative, selective laser melting makes possible not only filigree structures but any number of complex shapes. The huge advantage: With the right design and reliable production, additively manufactured metal parts meet the strictest requirements in terms of durability, stability and service life.

Thus the positive forecasts for the technology’s success. In a study published in 2022, Allied Market Research predicted that the market volume for metallic 3D printing would be $14.1 billion by 2031. And, according to the experts, the greatest potential for growth within this segment is in LPBF technology – which makes it worth paying special attention to in terms of its sustainability.

Sustainability, as viewed from many perspectives

‘Sustainable manufacturing’ is a broad concept. Numerous criteria can be used to effectively assess sustainability. When it comes to selective laser melting, three aspects are usually foremost:

- Freedom in component design leads to innovative products that are sustainable in their application. For example, automotive or aerospace components can be designed with cavities or internal structures that reduce their weight – and therefore the energy consumed during operation.

- Technology makes possible the individualized production of spare parts, so that product functionality can be guaranteed for a longer time. Plus, stoppages are kept to a minimum if spare parts can be manufactured quickly. Both contribute to a better ecological bottom line.

- Parts are designed digitally on a CAD model, from which they are directly realized as a developed structure. Although a few support structures are still required to ensure stability during production, the volume required has been significantly reduced by further refinements in the (slicer) software. Compared to machining, the metal can be used much more efficiently, reducing demand for valuable raw materials.

Quality and reliability are decisive in the long term

One thing is especially important to keep in mind for sustainability: The advantages are only relevant if the quality of the manufactured components is consistently high. As soon as the machines start producing rejects, the eco-balance plummets. The quality of both the materials used and the focused laser beam(s) are crucial. Indeed, the importance of the laser parameters has long been underrated in the execution of selective laser melting. While measurement of these parameters is paramount during the design phase of LBPF systems, once those systems are on the job, all bets are off! The focused laser beams frequently go long unchecked between construction projects.

In recent years, a change in thinking has positively impacted the technology’s sustainability, as described by Sven Schipper, MKS Sales Engineer for Ophir measurement technology: “We’ve seen a clear trend toward regular measurements by the user over the last two years. It’s often a question of ensuring the production quality of complex components that are exposed to heavy loads. The continuous monitoring of the laser parameters prevents the generation of rejects – and even the use of too much energy – in processing. In terms of sustainability, both pay off.”

As build chambers get larger, measuring technology gets smaller

Developments in selective laser melting are advancing by leaps and bounds. Not only are the sizes of the build chambers much more variable, with several lasers being used simultaneously to melt the metal powders, now there are also systems equipped with lasers in the green/blue spectrum for use with highly reflective materials such as copper. The good news for end-users? The technology for measuring the lasers in the build chamber is keeping pace with advancements. The industry is adapting to the needs of its users, both in terms of the spatial conditions and the types of laser beam sources employed.

Powder beds: Even when high laser powers are in use, measurements still need to be possible without additional water cooling. Robust measuring devices protected by a housing are ideal.

Closed build chambers: Here, measurement is made much simpler if the measuring device operates autonomously, without additional wiring to the outside, since the construction chamber may be completely sealed off.

Different wavelengths: This calls for versatile devices that work not only in the NIR range but also in the green/blue spectrum, for use in e.g. additive manufacturing of copper components.

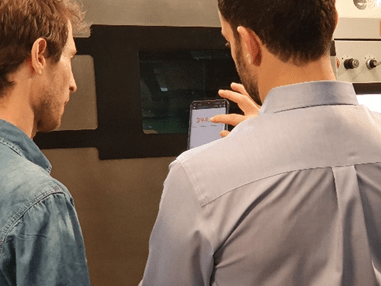

Manufacturers such as MKS have taken these requirements to heart and added two more instruments to their portfolio of Ophir measuring technology for LPBF systems. The Ophir Ariel power meter is extremely compact – fitting in the palm of your hand – and works completely autonomously. Power is supplied by a built-in rechargeable battery; data is transmitted from the measuring chamber via Bluetooth. And recently at Photonics West, the company introduced its new StarViewer iOS app, which allows the Ariel to be controlled via iPhones or iPads. The device is also suitable for green and blue lasers.

For users who want to record the beam profile in addition to the power, the company has developed the Ophir BeamPeek™ analyzer. Thanks to a specially developed cooling system with exchangeable plug-in units, the power and beam profile of the laser can be determined quickly and without cool-down breaks between successive measurements. The laser beam enters the system and hits a beam splitter that directs a small fraction of it onto the camera. The main body of the beam is further split, with one part landing on an integrated thermal sensor that can measure up to 1kW for two (2!) minutes at both green (532nm) and NIR (1030-1080nm) wavelengths.

Holistic approaches to sustainability

Selective laser melting is a complex process in which all components must be optimally coordinated. Sven Schipper sums it up thus: “Additive manufacturing offers the best conditions for sustainable manufacturing. Knowing and optimizing the laser power and, if necessary, the beam profile of the focused laser beam is only one piece of the puzzle, albeit an important one. Of course, whether a process is actually sustainable depends on numerous other factors. If, however, you can perfectly align the atmosphere in the building chamber, the quality of the powder used and the properties of the laser beam, then you can avoid producing scrap while increasing the energy efficiency and reducing the amount of material consumed.”

Subscribe to receive laser news beamed to your inbox

Pick the subjects that are most relevant

- Industry news

- Power & Energy Meters

- Laser Beam Profilers

- LED Measurements